PaintExpo 2026 shows how AI and automation are changing surface technology

Artificial intelligence and automation have long been an integral part of industrial surface technology.

Artificial intelligence and automation have long been an integral part of industrial surface technology. Whether process monitoring, quality assurance, material efficiency or plant control – digital technologies are fundamentally changing painting processes and raising them to a new level of performance. PaintExpo is responding to this development and, from 14 to 17 April 2026, will be focusing on intelligent, automated solutions that are already in use today and will become even more important in the future. Close cooperation with manufacturers, system providers, research institutions and users shows that: AI is no longer a promise for the future, but a decisive lever for more efficient, sustainable and stable coating processes.

AOM-Systems is a major player when it comes to sustainable processes and error minimisation in the wet paint process. Data generated by AOM forms the basis for the AI that automates and optimises customer processes. This enables users to use AI to correct errors in the spraying process in a targeted and immediate manner. In return, the AI sends the operator a message indicating the exact cause of the error in the process. This reduces production errors and minimises paint, energy and electricity consumption. Thus, AI now contributes directly to resource conservation and better use of production resources. “A major OEM had to achieve a minimum coating thickness and therefore specified a high safety factor to ensure that the minimum coating thickness was achieved even with minor process fluctuations. With spray from AOM, they can now control 100% of the coating application in real time. This saves a huge amount of coating thickness, material and alternative downstream checks, and therefore money," explains Managing Director Dr Meiko Hecker, using a practical example to illustrate the benefits for users. During PaintExpo, AOM-Systems will focus on the integration of spray monitoring directly into the atomiser.

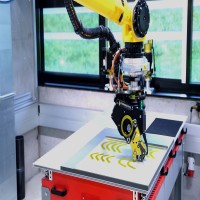

Convergent Information Technologies GmbH, a leading global software supplier for paint repair using robots, also utilises various forms of AI and machine learning. “This enables the automation of complex applications that seemed unthinkable just a few years ago. They allow for shorter start-up times, greater production flexibility and faster integration of new products," explains Managing Director Dr.-Ing. Christof Eberst. At PaintExpo, Convergent IT will showcase the next generation of automated planning for paint repair using robots and other surface processes. New input options for easier robot programming will also be presented, especially for cost-effective systems.

At Dürr Systems AG, the focus is on automation for wet paint systems. At PaintExpo, Dürr will be demonstrating overspray-free painting with the EcoPaintJet live and presenting the further development of the EcoSupplyP Core material supply system. This is a modular paint supply system with pigging that can be used wherever different paint colours are applied in small quantities, such as in the construction and wood industries or by automotive suppliers. Unused paint can be recovered almost completely, minimising the consumption of detergent and speeding up the colour change. With the EcoPaintJet, overspray-free paint application made its way into industrial vehicle painting, which paints with sharp edges and without any overspray. Now other industries are also benefiting from this solution.

ESS Engineering Software Steyr GmbH specialises in automating the pre-processing step in meshing. This commitment to process automation extends across the entire simulation workflow. Thanks to automation, the solutions achieve considerable time and efficiency gains. For example, vehicle development time can be reduced by up to one month and operating costs can be cut by around 30 per cent. ESS solutions also enable reduced prototype costs, faster optimisation and less dependence on experts. Instead of around 600 kWh for painting a vehicle, ESS's new patented painting technology reduces the energy requirement per car body to 200 kWh. In conjunction with CO2 reduction, increased material efficiency and waste prevention thanks to digital prototypes, ESS customers save significant resources. At PaintExpo, ESS will showcase a range of automated processes and workflows covering the entire simulation process.

As a leading developer of end-of-arm tools for sensitive surface processing – such as grinding, polishing or deburring – FerRobotics Compliant Robot Technology GmbH occupies a key position at the interface between high-precision mechatronics and advanced automation. With the help of its patented Active Compliant Technology (ACT), the company is transferring sensitive manual processes to robot-assisted series production. ACT-based tools guarantee precision through active force control, automatic tolerance compensation and AI-optimised calibration, resulting in 100% reproducible results and enabling perfect finishes even on sensitive surfaces. At the same time, efficiency increases while process reliability is enhanced and the reject rate is minimised. At PaintExpo 2026, FerRobotics will present the Active Taping Kit (ATK), a solution for automated masking and a unique method for repairing paint defects on plastic (AOK 403), as well as new processing strategies for fast and intuitive programming.

Automation and AI are also relevant in powder coating. As an application manufacturer, Gema Switzerland GmbH has been relying on intelligent, networked control systems and control software for some time now, such as the MagicControl 4.0 system, which offers a powerful automation interface. In addition, selected concepts from Industry 4.0 can be profitably applied in the powder coating process. Production data is continuously recorded, processed and visualised in a clear and informative manner using tools such as the GemaConnect® Dashboard. The resulting added value for powder coating customers is material savings and increased efficiency. Precise control optimises the amount of powder used, which means less overspray and therefore less material consumption. However, AI and automation can also serve to achieve higher quality and consistency, relieve the burden on workers, improve process control and traceability with networked systems and real-time data, and increase safety for operating personnel. At PaintExpo, Gema will be presenting a wide range of integrated functions that continuously improve industrial powder coating and support the sustainable use of resources.

Automation also plays a central role at M&N Fördersysteme GmbH. The conveyor technology ensures a continuous, stable flow of materials and guarantees that all process steps in surface technology are precisely coordinated. This enables M&N's customers to achieve high process reliability, efficiency and reproducible quality. Automated conveyor technology also makes an important contribution to conserving resources, as continuous and precisely controlled transport of workpieces reduces downtime and idle time, minimises reworking and ensures optimum utilisation of the coating systems. This leads to lower energy consumption, less waste and more efficient processes overall. In Karlsruhe, M&N is focusing on new, advanced rotary transfer systems and optimised control and guidance systems that offer greater flexibility in cycle times and workpiece variants, improve the energy efficiency of the drives and enable an even more continuous, automated material flow.

In paint and coating development, ML-supported analysis methods enable formulations, recipes and application processes to be understood much more quickly and thoroughly. Pi Probaligence develops ML algorithms that are used across industries in product development, process control and simulation. These models are increasingly being incorporated into control software, where they enable intelligent predictions and assistance functions. The more data-rich and automated a process is, the more effectively Pi Probaligence solutions can be used. In product development, ML enables data-efficient, exploratory experimental design that searches parameter spaces in a targeted manner. This either finds an optimum or creates a digital twin that virtually maps complex real chemical and physical systems. At PaintExpo 2026, Pi Probaligence will present specific applications from industry and research and introduce a new interface with natural language control and automated connection to existing tools.

AI and automation as integral components of networked coating processes

The applications presented illustrate that AI and automation in surface technology are no longer viewed in isolation, but increasingly as integral components of continuous process chains. The focus is shifting from individual optimisations to networked systems in which process data, quality information and plant parameters are collated and evaluated in real time. This development opens up new potential for reproducible quality, resource efficiency and process stability – but at the same time requires a high level of system integration and robust data models. PaintExpo 2026 reflects this technological maturity within the industry and provides a platform for professional exchange on the practical application, limitations and further development of AI-supported solutions in industrial surface technology.