Exhibitor Press Release

TRADE FAIR PREMIERE: High-performance powder coatings – process reliability, time savings and reduced consumption all in one

Pulverit Deutschland GmbH

This series offers the following key advantages:

- Very high loading capacity and high initial application efficiency

- Very good penetration behaviour, even in Faraday cages

- Very homogeneous powder coating structure

While the first two points have a particularly positive effect on application and simplify and accelerate the coating process, the third point is of great interest, especially from a purchasing and cost perspective. Thanks to the particularly homogeneous powder structure, only the amount of powder that is actually required according to your technical specifications can be used.

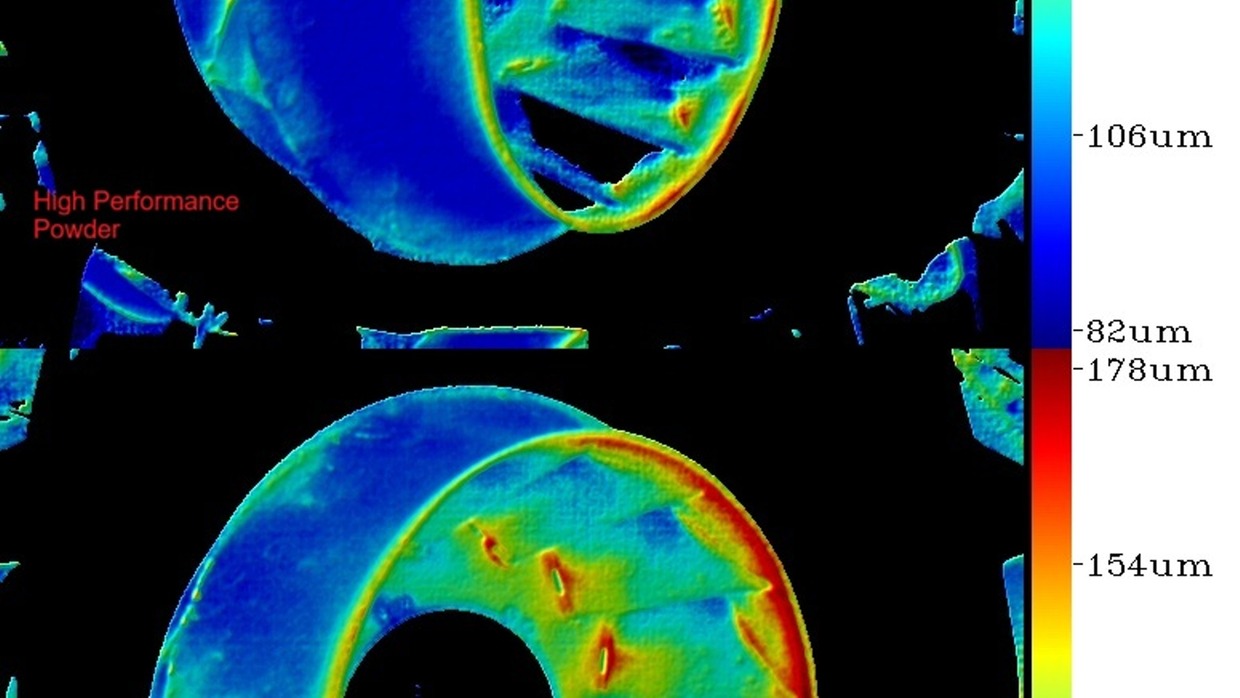

Excessive layer thicknesses – for example, in the edge area or as a result of Faraday cages – are reduced to a minimum. Depending on the component geometry, this enables powder savings of approx. 10 to 22%. As can be clearly seen in the attached illustrations, the standard powder shows a typical layer thickness distribution of approximately 80 µm (dark blue colouring) to well over 180 µm (red colouring). A large proportion of the surface is already above 120 µm (green and yellow colouring). The identical article, coated with the high-performance series, on the other hand, has a significantly more homogeneous layer thickness distribution.

The majority of the coating is in the range of 80 µm (blue colouring); only in the outermost areas are higher layer thicknesses found (green, yellow and orange). This opens up previously untapped potential for you to save powder in a targeted manner where it is not technically necessary.

Contact:

Pulverit Deutschland GmbH

Sandro Albano

017662717686

s.albano@pulverit.com