Exhibitor Press Release

NEW PRODUCT: Complete Turnkey Solution for Paint Defectfree Car Bodies: Automatic Defect Detection, Positioning & Repair

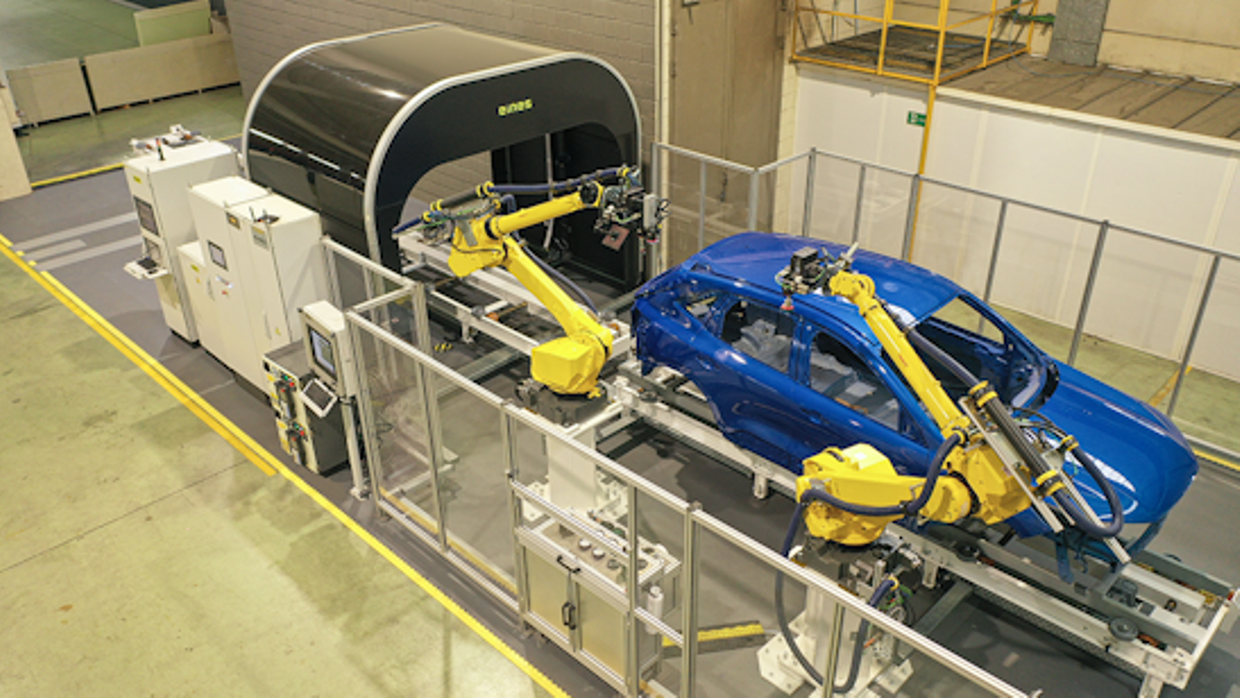

EINES SYSTEMS SLU

EINES presents an integrated, fully automated tunnel solution that combines ESFI (EINES Surface Paint Quality Inspector) with the AutoRepair robotic repair system to create a closed, digital inline process for the detection and autonomous repair of paint defects. The ESFI system uses advanced AI algorithms and high-resolution optical technologies to precisely detect, classify, and locate surface defects such as dust inclusions, craters, runs, or scratches—directly on the production line and without stopping production. Each detected defect is measured in three dimensions and digitally mapped. This data is automatically transferred to the AutoRepair system. Based on the exact position and classification data, AutoRepair performs fully autonomous grinding and polishing processes with millimeter precision – either inline or in stop-and-go mode, depending on customer requirements. The seamless integration of inspection and repair creates a closed loop between defect detection and corrective action.

What makes this innovation special is the complete automation of the entire workflow: paint defects are not only identified, but also automatically corrected without subjective human evaluation. The system reduces operator dependency, minimizes rework and scrap, increases process stability, and ensures complete digital traceability for quality analysis and continuous process optimization. With ESFI + AutoRepair, EINES enables OEMs and tier suppliers to achieve a resilient, scalable, and future-proof paint process architecture with the goal of a sustainable zero-defect strategy.

Contact

EINES SYSTEMS SLU

Patricia Adam Castelló

667636783

patricia.adam@eines.com